Our foundry’s operations are supported by a skilled team of technicians, engineers, and machine setters. The increasing quality demands and expectations necessitate continuous professional and technological development. Our company operates an internship program through which we ourselves train university students and vocational school students who join us. Together with them, we test and develop the technologies and tools that are to be introduced. We have achieved significant results in the use of cooled chambers and ring injection pistons, the development of mold venting systems, and implementing mold release with minimal lubrication. To achieve better efficiency and readiness, we design, develop, and use special-purpose machines. Custom saws, milling machines, deburring, and polishing machines assist in production.

In the foundry, we use various material testing equipment and methods to ensure customer expectations. We analyze the melt composition using a spectrometer, measure the gas content of the melt using density index measurement and

we check the inclusions content with K-Mold test. We monitor the proper tool thermal management through thermal camera analysis, we perform porosity testing of our products with RTG/CT equipment, and analyze the microscopic images and polished sections.

The finishing area of the foundry operates with 30 employees and is equipped with modern surface processing equipment. According to customer requirements, we use ceramic abrasive blasting and Cr-containing shot blasting, and this area also handles final inspection and packaging. During the abrasive blasting, we use Rösler continuous abrasive equipment with various stone sizes, several sizes of Trowal circular vibrators with rinsing and drying functions. Shot blasting is also possible with different shot sizes according to requirements. We use Rösler shot blasters with continuous wire mesh, hanging, and rubber belt types, and ABRAZIV custom-made equipment is also in use.

The production of molten metal is the task of the smelting plant, where modern gas-fired, two-pit furnaces operate, separated separately for each alloy.

Melting furnaces with a capacity of 2/1 ton

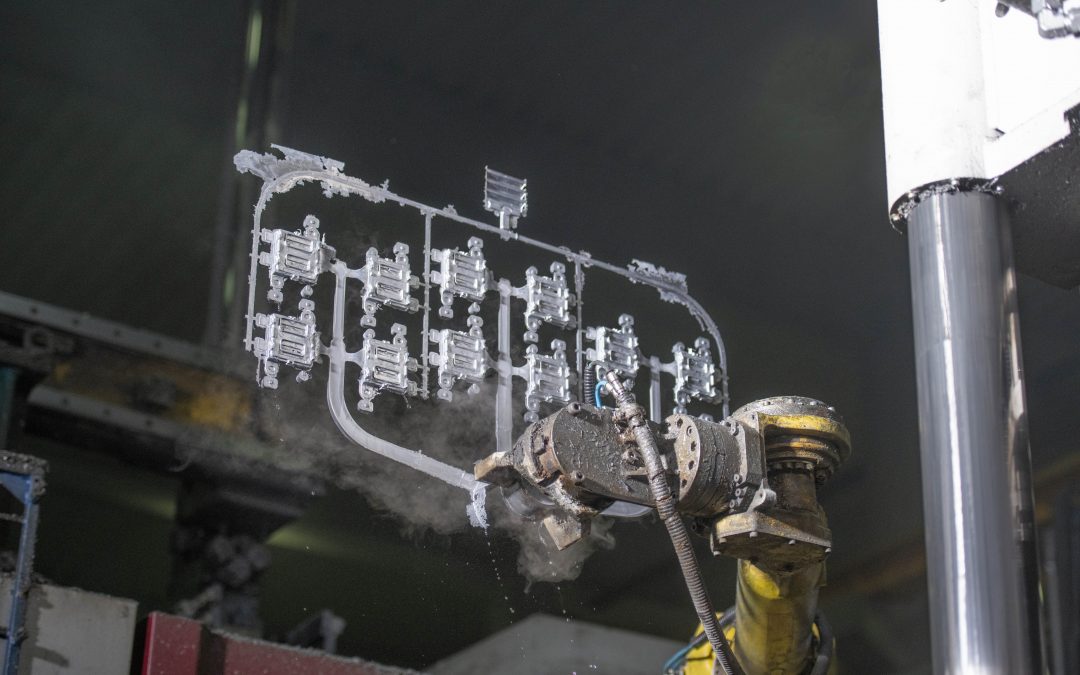

Ecseri Ltd.'s main activity is aluminum pressure die casting. Pressure die casting is a mechanized version of casting where the molten metal is forced into a metal mold at high speed with the help of a die piston, where high pressure during solidification eliminates volume changes due to phase transitions.

The metal molds, or die tools, used in pressure die casting allow for the production of thin-walled, complex geometrical, and dimensionally accurate parts, in large quantities and with high durability.

Our current machinery allows for the production of castings ranging from as low as 20g to 10kg in 1 to 12 cavity molds.

Our casting capacity is 29 horizontal, cold-chamber, high-pressure casting machines in the closing force range of 400t...2400t. Most of the cells are fully automated, with a custom-developed production data registration system. Most of our machines are made by FRECH, but there are also MAICO and IDRA casting machines in the factory. In the casting cells, Striko Westofen, Krown and Foundry feeding furnaces keep the molten metal at the right temperature and deliver the molten metal to the casting machines, Wollin and IDRA blow-off equipment ensure mold handling, FANUC robots move the casting bunches, Robamat and ToolTemp tool temperers control the temperature of the casting tools, some are removed with REIS presses cut and air pockets away from the parts. Our casting tools have a 1...12 nest design and are made in our own tool factory.