Production

Learn about our production processes!

During Ecseri Kft.'s melting process, aluminum alloys are melted using StrikoWestofen furnaces. Our facility has 7 of these melting furnaces, capable of holding up to 2 tons of molten aluminum at a time. The aluminum is maintained at a constant 750°C to ensure quality. We use both primary and secondary materials in the melting process, producing five different casting alloys. Our hourly production capacity reaches 1 ton of melt, enabling fast and efficient manufacturing.

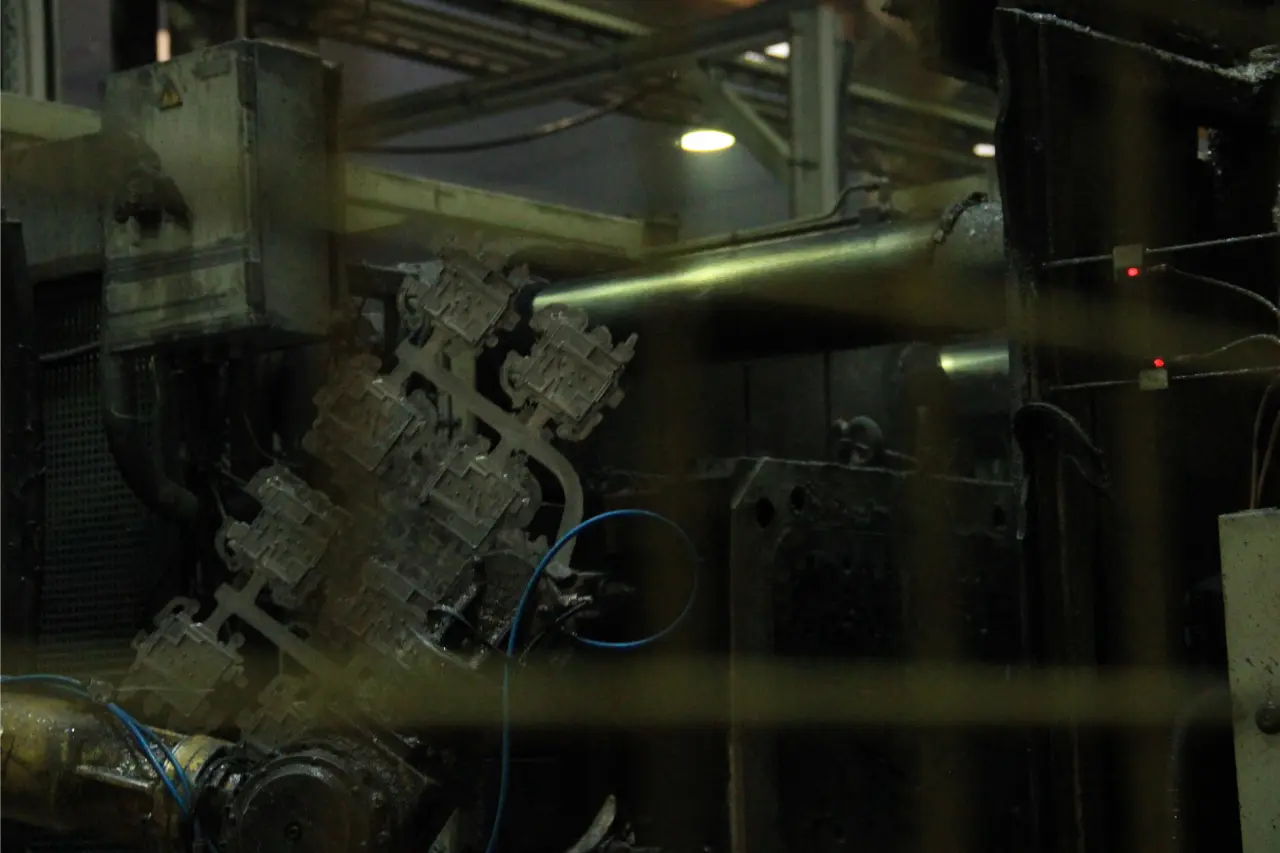

Ecseri Ltd.'s main activity is aluminum pressure die casting. Pressure die casting is a mechanized version of casting where the molten metal is forced into a metal mold at high speed with the help of a die piston, where high pressure during solidification eliminates volume changes due to phase transitions.

During trimming, excess materials and burrs are removed from the castings to prepare them for further processing. Precision is essential in this process to ensure the desired quality.

Abrasion is primarily a process used for the mechanical surface treatment of metal workpieces. The abrasion process is determined by the combined effect of the equipment, the abrasive body and the abrasive fluid. Due to the vibrating or rotating movement of the work container, a relative displacement is created between the surfaces of the abrasive bodies and the workpieces. Almost all of them are made of metal, plastic and ceramic, and come in a wide variety of sizes and shaped workpiece can be worn in an economical and environmentally friendly way. Abrasion (trovalization) operations: deburring, polishing, surface cleaning, rust removal

During the blasting process, small-sized particles made of different materials are delivered to the workpieces to be cleaned with high-pressure compressed air. As a result of friction, the particles impacting with high energy remove and wear away the surface layer of the material to be cleaned, so it becomes metal clean.

During Ecseri Kft.'s heat treatment process, we use three furnaces to maintain the castings at 200°C. This temperature improves machinability and modifies mechanical properties according to customer requirements. We test yield strength, elongation, and tensile strength during the process to ensure that the castings meet the highest quality standards.

During cutting, we use CNC machines to precisely shape the surfaces, holes and threads, thus ensuring that the parts fully meet the technical requirements. Our multi-axis CNC equipment from long-established machine manufacturers, as well as top-quality machining tools and sophisticated technologies guarantee the excellent quality and perfect workmanship of our products.

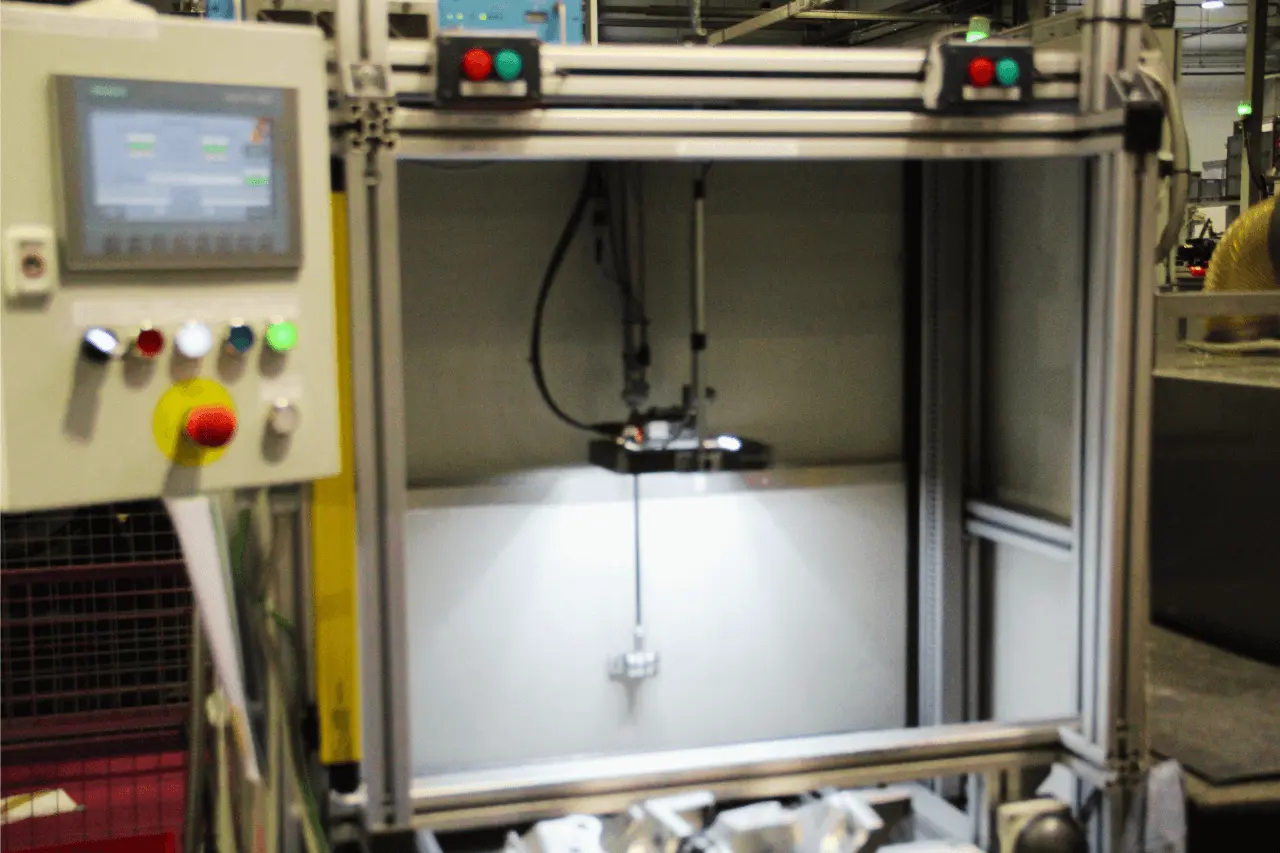

During product inspection, we thoroughly examine the finished products to ensure their quality, reliability, and compliance with specifications.

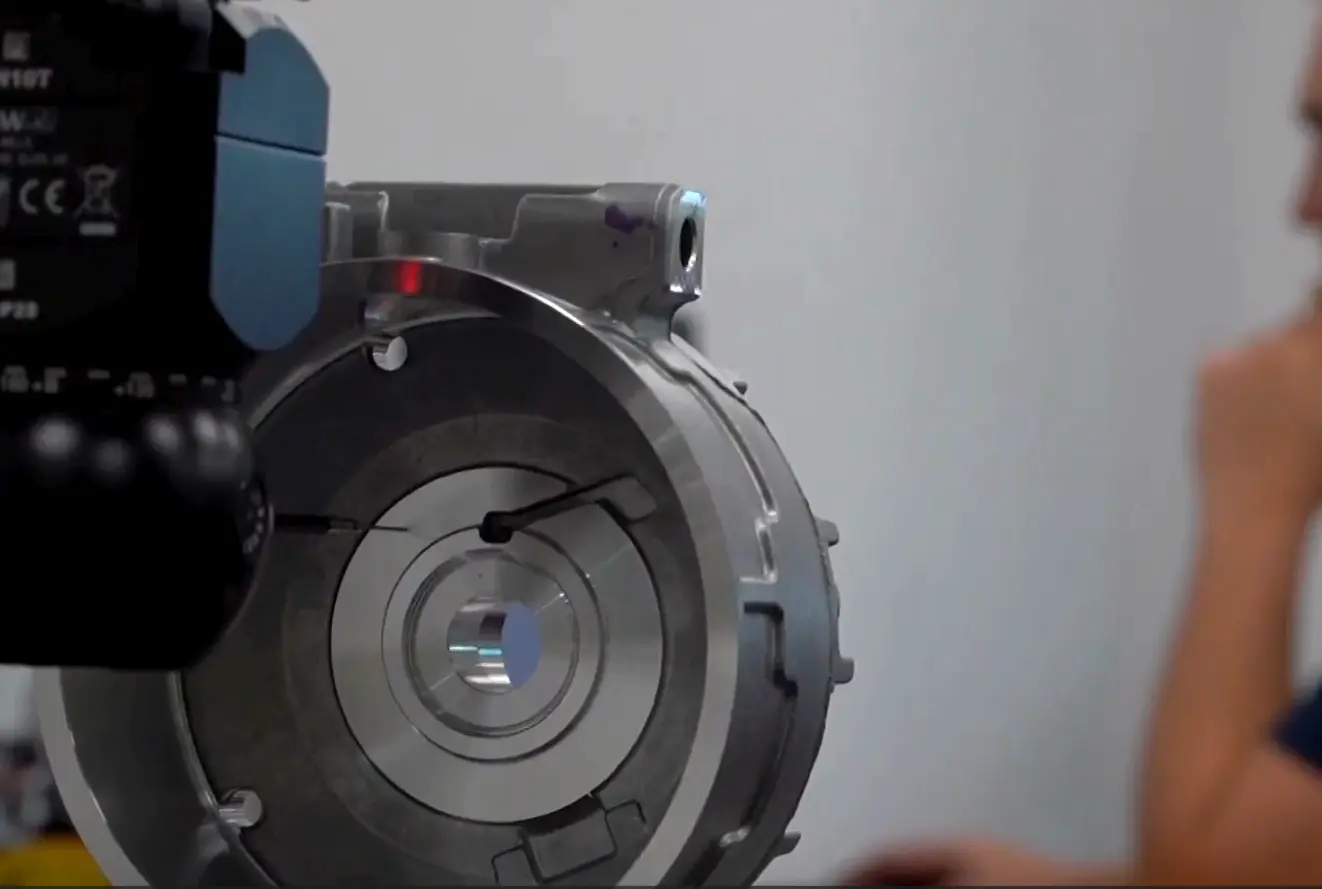

The purpose of the pressure test is to check the leak-freeness of the products, in order to ensure that they meet the technical specifications. During the process, we check the gas tightness of the casting, based on the customer's specifications for the product.

During product marking, we provide products with unique identifiers to ensure their traceability and quality control. Such identifiers, such as DMC or engraved codes, allow us to trace back the manufacturing data for the product.

During cleaning, we remove any dirt, oils and other residues from the surface of the products. In accordance with cleanliness requirements, the products are washed according to the customer's specifications and then packed. This ensures that the cleanliness requirements are met.

During our assembly operations, we assemble the semi-finished products prepared by us in accordance with the customer's requirements. With the help of our unique, product-specific assembly machines, we are able to perform any assembly operation.

During packaging, the finished products are packaged with appropriate materials to protect them during transport and ensure their integrity until they reach the customers.